**

Imagine a braking system that never wears out. One that stops heavy loads with whisper-quiet elegance, generates zero dust, and shrugs off extreme environments like it's nothing. Sounds like science fiction? Enter the world of **Hysteresis Brakes** – the unsung heroes of precise, frictionless control. Forget the screech and spark of traditional brakes; this is where magnetism performs a silent symphony of stopping power. 🎻🧲

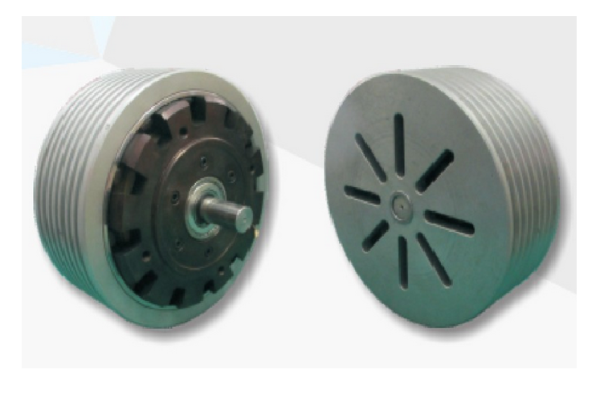

Forget everything you know about brake pads grinding against discs. Hysteresis brakes work on an entirely different principle: **electromagnetism**. At their heart lies a simple, yet brilliant interaction. Picture this: A smooth, non contact rotor spins freely. Surrounding it? An electromagnetic coil. When you energize that coil, it creates a powerful magnetic field. This field *penetrates* the rotor material (usually a special high hysteresis alloy), inducing eddy currents within it. These eddy currents generate their *own* opposing magnetic field. The magical tug of war between these fields – the primary field from the coil and the secondary field induced in the rotor – creates a pure, controllable torque resistance. That resistance is your brake force. No touching. No rubbing. Just pure magnetic persuasion. ✨

Why does this matter? Let’s break down the superpowers bestowed by this unique technology:

1. **Frictionless Operation, Infinite Life 🔄:** The core advantage. Since there’s no physical contact between the brake components, there is **zero mechanical wear**. No pads to replace, no discs to resurface. This translates directly to dramatically reduced maintenance costs, less downtime, and near infinite operational lifespan. Think decades, not months.

2. **Exquisite Torque Control \u0026 Linearity 📏:** The torque produced is incredibly smooth and directly proportional to the input current to the coil. Need a tiny, precise holding force? Deliver a small current. Need maximum braking torque? Ramp up the current. This offers unparalleled accuracy for tensioning, load simulation, testing, and controlled deceleration. The torque is consistent and predictable, unaffected by rotational speed within their operational range. Smooth as silk.

3. **Silence is Golden 🔇:** No physical contact means no noise. No grinding, no squealing, no clattering. Just the gentle hum of electromagnetism. This is a game changer in environments demanding quiet operation: medical labs, sound studios, libraries, hospitals (MRI compatibility is a big plus!), and luxury automation.

4. **Cleanliness Champion 🧼:** No friction equals no brake dust, no oil mist, no debris. Critical for cleanroom applications (semiconductor manufacturing, pharmaceuticals, food processing), printing, textile handling, and anywhere contamination is the enemy. Your environment stays pristine.

5. **Built Tough ⚔️:** The non contact nature inherently makes hysteresis brakes incredibly robust. They are generally sealed units, impervious to dust, moisture, oil, and other harsh environmental contaminants that plague mechanical brakes. They excel in demanding settings like marine applications, heavy machinery, and outdoor equipment.

6. **Heat? What Heat? ❄️:** While they *do* generate heat due to the eddy currents (the hysteresis loss), this heat is dissipated *through* the rotor itself and managed via design. Crucially, the heat generation is consistent and controlled, avoiding the localized, destructive hot spots common in friction brakes during repeated or high energy stops. Cooling fins or forced air often suffice.

7. **Inherently Safe 🛡️:** Many hysteresis brake designs offer a failsafe feature. If power is lost, the magnetic field collapses, and the brake inherently releases. No risk of a \"locked on\" failure mode that could damage equipment. Conversely, spring applied versions can be designed to engage on power loss for holding safety.

So, where do these magnetic marvels actually shine? Their versatility is astounding:

* **Test \u0026 Simulation Labs 🧪:** Hysteresis brakes are the gold standard for dynamometers and test stands. Need to simulate precise load profiles on engines, motors, transmissions, or even human power (bicycle ergometers)? Their linear torque control and smoothness are unbeatable. Think automotive R\u0026D, aerospace component testing, material fatigue testing.

* **Tension Control Mastery 🧵:** Maintaining perfect tension is crucial in winding/unwinding applications. Paper mills, film processing, wire drawing, textile weaving, cable manufacturing – hysteresis brakes provide the precise, jitter free torque needed to prevent slack, snapping, or wrinkling. They respond instantly to control system signals.

* **Medical \u0026 Laboratory Precision 🏥:** The silence, cleanliness, and precise control are vital here. Think centrifuge brakes, robotic surgical arm positioning, analytical instrument control, and patient handling equipment within MRI suites where ferrous materials are forbidden (non magnetic rotors can be used!).

* **Entertainment \u0026 Robotics 🎭🤖:** Smooth, silent motion is key for camera dollies, animatronics, stage automation, and high end robotics. Hysteresis brakes provide controlled stops and holding without jerking or noise pollution.

* **Aerospace \u0026 Defense ✈️:** Demanding environments? Check. Need reliability? Check. Precision control? Check. Hysteresis brakes find use in antenna positioning, gyro stabilization, missile fin actuation testing, and simulator platforms.

* **Material Handling \u0026 Automation 🏗️:** Conveyor indexing, robotic arm end effectors requiring controlled release, baggage handling systems needing gentle stopping – the robustness and control shine.

* **Renewable Energy 🌬️☀️:** Used in pitch control mechanisms for small wind turbines and solar tracker positioning systems, benefiting from the high duty cycle and environmental resilience.

* **Packaging Machinery 📦:** Maintaining consistent tension on labels, film, and packaging materials during high speed operation, crucial for quality and preventing jams.

Let’s get a bit more concrete. Imagine a high speed film coating line. Miles of delicate film race through rollers. Consistent tension is non negotiable; too loose, and the coating is uneven; too tight, and the film snaps, causing expensive downtime and material waste. A traditional friction brake, battling dust and wear, struggles for precision. Enter a hysteresis brake on one of the winding shafts. Controlled by the line's PLC, it applies the *exact* torque needed, millisecond by millisecond, to maintain perfect tension. No dust contaminates the clean film. The brake itself will likely outlast the entire production line. That’s the tangible impact.

Or consider a state of the art physical therapy clinic. A patient is rehabilitating a knee injury using a motorized dynamometer. The machine needs to apply precisely controlled resistance through the entire range of motion, measuring strength and recovery progress. A hysteresis brake provides the smooth, consistent, and adjustable resistance required, all without the distracting noise or mechanical jolt of a friction system, creating a better patient experience.

Now, how do you *control* this magnetic force? That’s where the driver comes in. While a simple DC power supply can provide basic on off control, the real magic happens with sophisticated brake controllers. These units translate your desired torque command (often an analog voltage signal like 0 10V DC or a digital signal) into the precise current needed for the brake coil. Advanced controllers offer features like:

* **Torque Profiling:** Ramping torque up or down smoothly to avoid jerk.

* **Closed Loop Control:** Using feedback (e.g., from a torque sensor) to ensure the *actual* torque matches the *commanded* torque perfectly.

* **Dynamic Braking:** Using the brake to absorb energy during deceleration and managing the resulting heat dissipation effectively.

* **Communication Interfaces:** Integration with PLCs, PCs, or industrial networks (EtherCAT, CANopen, Modbus etc.).

Selecting the right hysteresis brake involves careful consideration:

* **Required Torque Range:** Peak and continuous torque values needed for your application.

* **Rotational Speed:** Operating RPM range of your shaft.

* **Inertia:** The inertia of the load being braked influences stopping time/distance.

* **Duty Cycle:** How frequently will the brake be energized and dissipating heat? Continuous operation requires robust thermal design.

* **Environmental Conditions:** Temperature extremes, humidity, dust, chemical exposure. Sealing and materials matter.

* **Mounting \u0026 Shaft Interface:** Size constraints, shaft diameter, keyway requirements.

* **Control Input:** Simple DC or requiring a sophisticated controller? What signal type?

* **Heat Dissipation:** Can the brake radiate heat effectively in its location, or is forced cooling needed?

It’s tempting to compare hysteresis brakes to their more common cousins:

* **vs. Friction Brakes (Disc/Drum):** Hysteresis wins hands down on wear life, silence, cleanliness, control smoothness, and often heat management in cyclic applications. Friction brakes usually win on initial cost for very high torque, low duty cycle applications and offer mechanical \"lock\" without continuous power.

* **vs. Eddy Current Brakes:** Often confused, but distinct. Eddy current brakes rely *only* on induced eddy currents (from a changing magnetic field relative to the conductor) to generate braking force. They typically require relative motion *and* are generally speed dependent (torque increases with speed). Hysteresis brakes generate torque primarily from the magnetic hysteresis *loss* within the rotor material itself and can exert significant torque even at near zero speed. They offer better low speed control. Eddy current brakes are often simpler/cheaper for applications like high speed vehicle retardation.

* **vs. Powder Brakes:** Powder brakes use magnetic fields to lock ferromagnetic particles, creating a shear force. They offer high torque density but involve friction *within* the powder, leading to wear, heat generation, and potential torque drift over time. Hysteresis wins on life, cleanliness, and torque linearity.

The future of hysteresis braking is bright, driven by demands for greater precision, reliability, and efficiency:

* **Integration:** Brake and controller units becoming more compact and intelligent.

* **New Materials:** Research into advanced magnetic alloys and composites promises higher torque density and better thermal properties.

* **Smart Features:** Embedded sensors for torque feedback, temperature monitoring, and predictive maintenance capabilities directly within the brake unit.

* **Wider Adoption:** As awareness grows and costs become more competitive, expect to see hysteresis brakes penetrating deeper into automation, robotics, consumer products, and emerging tech like advanced prosthetics and exoskeletons.

Hysteresis brakes are not a flashy, screaming headline. They are the quiet confidence behind millions of precise motions happening right now, unseen but essential. They are the assurance of reliability measured in decades, not service intervals. They are the enablers of silence in noisy worlds and cleanliness in critical processes. They transform brute stopping force into a controllable, elegant art form.

For engineers, designers, and operators wrestling with the limitations of friction – the wear, the noise, the mess, the unpredictable torque – the hysteresis brake offers a compelling alternative. It’s an investment not just in a component, but in long term performance, reduced operational headaches, and superior product quality. It’s the unseen force you can truly rely on. 💪🧲

When the demands of your application exceed what friction can gracefully deliver, when precision, silence, and longevity are non negotiable, look beyond the grind. Embrace the power of pure magnetism. Embrace the hysteresis brake . It’s not just stopping motion; it’s enabling perfection. 🎯🌌